EXTRUDED tube

Extrusion is one of the most popular technologies

in the manufacture of flexible plastic tubes.

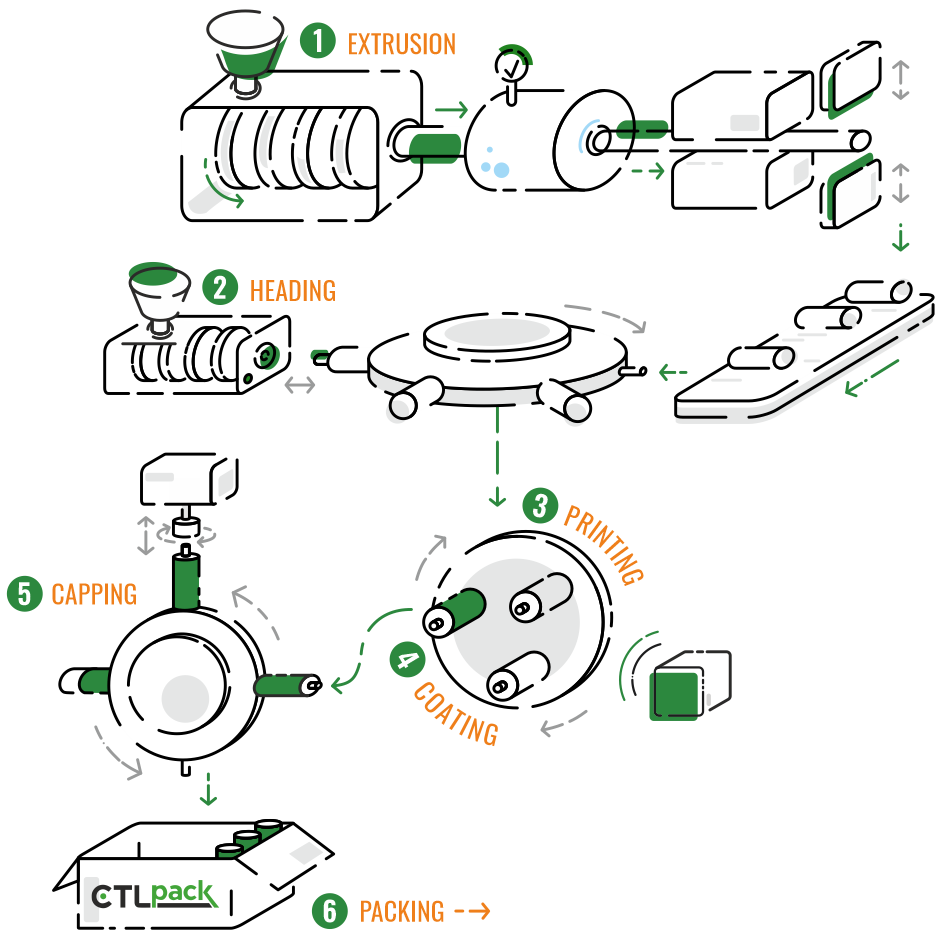

EXTRUSION

In this process, the polyethylene plastic compound in pellet form is melted inside the extruder machine which forms a continuous cylinder, either in a single or multi-layer construction, which is cut to the desired length to create the sleeve of the tube. Multilayer extrusion or co-extrusion makes it possible to combine polymers with different properties to ensure a more functional packaging with greater protection for the formula.

HEADING

The head is placed on the tube sleeve using the injection method. A wide range of heads is available depending on the type of cap to be used.

PRINTING

Once the tube (sleeve with head) is formed, the tube is decorated. Depending on the type of decoration, different types of inline printing technologies (dry offset, flexography) or auxiliary processes (screen printing, hot stamping) are used.

COATING

Once the tube has been decorated, it is generally varnished to protect the decoration.

CAPPING

Finally, the tamper evidence (if necessary) and the cap are fitted.

PACKING

Lastly, the tubes are packed to be sent to the customer.

1. EXTRUSION

In this process, the polyethylene plastic compound in pellet form is melted inside the extruder machine which forms a continuous cylinder, either in a single or multi-layer construction, which is cut to the desired length to create the sleeve of the tube. Multilayer extrusion or co-extrusion makes it possible to combine polymers with different properties to ensure a more functional packaging with greater protection for the formula.

2. HEADING

The head is placed on the tube sleeve using the injection method. A wide range of heads is available depending on the type of cap to be used.

3. PRINTING

Once the tube (sleeve with head) is formed, the tube is decorated. Depending on the type of decoration, different types of inline printing technologies (dry offset, flexography) or auxiliary processes (screen printing, hot stamping) are used.

4. COATING

Once the tube has been decorated, it is generally varnished to protect the decoration.

5. CAPPING

Finally, the tamper evidence (if necessary) and the cap are fitted.

6. PACKING

Lastly, the tubes are packed to be sent to the customer.

EXTRUDED

Tube Solutions Catalog

Contact

Contact