Timeline

SUSTAINABLE products

POSITOP

In 2006 CTLpack was already advocating sustainability by achieving a weight reduction of 35% on one of the most common caps in the tube world.

PCR

CTLpack researches new packaging materials, and in 2010 introduced a new tube made from PCR (post consumer recycled) material. This material, which comes from the recycling of other types of packaging, promotes the circular economy by reintroducing used plastic into the production chain.

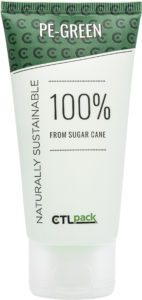

PE-GREEN

In line with increasing customer demands for sustainability, CTLpack expands its range of sustainable tubes with a new polyethylene tube made from sugar cane.

OCTOGONAL CAP

Due to its light weight, the octagonal cap is a good solution in terms of sustainability. Made of both polypropylene and polyethylene, it reduces the overall weight of the packaging and increases recyclability while presenting an attractive and original image.

ECO-f

Available in extruded tube, this packaging reduces plastic reduction by up to 28% compared to other tubes with similar characteristics. Thanks to the combination of the Minitop cap and the reduced thickness of the sleeve, it is the ideal choice for large format tubes.

MINITOP

Continuing with the premise of material reduction, CTLpack introduces the Minitop cap. With the same performance as any other hinged cap, this option features a much lighter design that decreases the overall weight of the tube by 8.5%. For example, for an order of 10,000 tubes, the MINITOP cap represents a saving of 21 kg of plastic compared to the Positop cap.

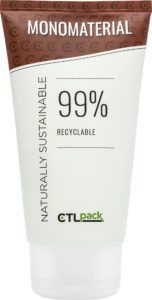

MONOMATERIAL

99% Recyclability rate according to the German Institute Cyclos (for Germany, Austria, Italy, The Netherlands, Norway and The United Kingdom)

Certificate N° 2319-2020-001529

Possibility of Post-Consumer Recycled Polypropylene (PP-PCR) only FDA NOL

Ø 35-40-50 mm

From 40 ml to 265 ml

ECO-f

Eco-friendly extruded PE tube solution combining 3-in-1 plastic weight reduction: in sleeve, head and cap

Available in Ø35, 40 and 50 mm

Thinner sleeve: 0,4 mm

Reduced cap: Minitop

Increased sustainability with possibility of biobased and/or PCR materials on the sleeve and head

Ø 50 mm PE tube

Coex

From 100 ml to 250 ml

PE-GREEN

Bio-Based Polyethylene material from sugar cane with Food Contact

100% recyclable components (sleeve and head)

Sugar cane is a renewable source. The plantations capture CO2 which reduces greenhouse gas emissions

This tube has been created from an innovative material that does not proceed from fossil petroleum, but from sugar cane grown in Brazil, in controlled areas and far from the Amazon rainforest

PE-PCR

Post Consumer Recycled Polyethylene material from plastic packaging with Food Contact

Mechanically recycled material

Sleeve up to 50% PE-PCR

Head up to 75% PE-PCR

Possibility of 100% PP-PCR cap

PP-PCR

Post Consumer Recycled Polyethylene material from plastic packaging with FDA NOL

Mechanically recycled material

Sleeve up to 15% PP-PCR

Head up to 50% PP-PCR

Cap up to 100% PP-PCR

PE- PCR ISCC+

Post-Consumer Chemically Recycled Polyethylene Mass Balance

Promotes the circular economy

Sleeve up to 98% PE-PCR Mass Balance

Head up to 100% PE-PCR Mass Balance

Cap up to 100% PP-PCR Mass Balance

PP- PCR ISCC+

Post-Consumer Chemically Recycled Polypropylene Mass Balance

Promotes the circular economy

Sleeve up to 47% PP-PCR Mass Balance

Head up to 100% PP-PCR Mass Balance

Cap up to 100% PP-PCR Mass Balance

NIR DETECTABLE

With the new black dye without carbon black, the component plastic material can be identified and sorted in the waste separation and sorting lines for proper recyclability.

These dyes have good opacity and retain the same printing characteristics as black with NC.

Available for PE and PP tubes.

Also available for caps.

How do we achieve more SUSTAINABLE products?

CTLpack

REDUCE

We have been studying the best way to lighten our products for more than 15 years. Because the less material used, the less energy is consumed to produce it.

In 2006, we were the first to create a lightweight hinge cap (Positop Light). And our latest innovation has been the launch of the ECO-f plastic pipe, which reduces the weight of the plastic by up to 28% compared to a classic pipe of the same format (diameter 50, length 155, capacity 200 ml, Positop).

CTLpack

RECYCLED MATERIAL

We manufacture packaging from post-consumer recycled material in polyethylene (PE) and polypropylene (PP). We are also working on circular solutions based on chemical recycling methods, both from plastic waste (circular polymers) and bio-based waste (renewable polymers).

CTLpack

REPLACE

Replacing fossil-based materials with more sustainable alternatives, such as plant-based materials (GREEN). In 2015, we certified GREEN PE to reduce the use of petroleum-based polymers.

CTLpack

RECYCLABILITY

Our packaging is designed to facilitate and promote recycling. In the injected tubular packaging version, CTLpack is the only company able to offer a PP mono-material product with a recyclability rate of up to 99%. We also work with mono-material solutions for Extruded and Laminated pipes.

years working for the environment

Although the European Union has determined that for 2030 all plastic packaging will be recyclable, reusable or compostable, at CTLpack we have been working for over 15 years to achieve this goal as soon as possible.

Contact

Contact